1. Why choose glass industry water treatment equipment?

A. The treated water used for glass edging enhances the cleaning efficiency of the edging cleaning machine, improves the transparency of tempered glass, reduces tempering defects, and prolongs the lifespan of ceramic rollers.

B. The treated edging wastewater can effectively avoid frequent blockages of the water inlet pipe of the edging machine, machine don't need shutdown for cleaning, refrain from glass edges burnted and extend the service life of the grinding wheel by 30%.

C. Avoid fine scratches on the surface of coated and large plate glass during the edge grinding and cleaning process.

D. Treated water decreases the frequency of water changes in the cleaning machine, saving production costs.

E. Without the water treatment machine, the edging circulation pool needs to be cleaned every six months.

F. Direct discharge of untreated edging wastewater does not comply with national standards.

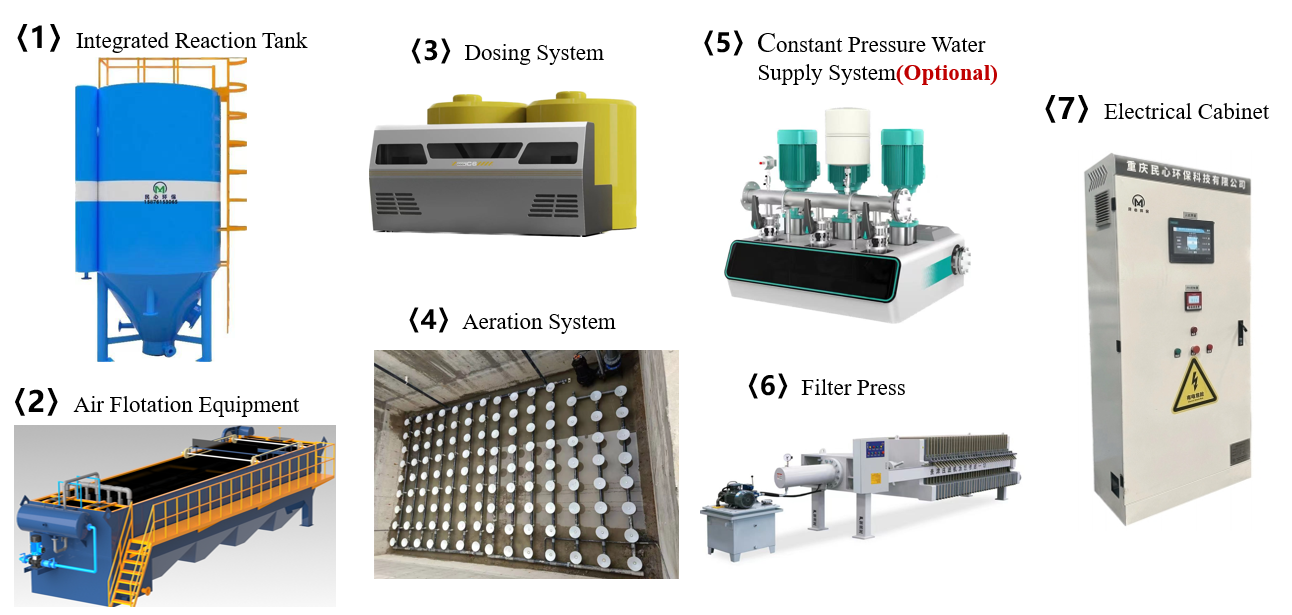

Our water treatment equipment is the perfect solution to these problems,this equipmentis including integrated reaction tank, dosing system, aeration system, constant water supply system, filter press and electrical cabinet.

2. Glass industry water treatment solution

![]() The treatment process involves pumping all wastewater generated by glass edging into our high-efficiency integrated reaction tank for treatment. The treated water is then discharged into a clean pool and recycled for glass edge grinding, significantly reducing blockages and damage to the water outlet of the glass edge grinder, thereby extending machine service life and improving grinding efficiency. The glass dust slag processed by the reaction tank is discharged into the sludge pool, then pressed into solid glass plates by the filter press to prevent environmental pollution.

The treatment process involves pumping all wastewater generated by glass edging into our high-efficiency integrated reaction tank for treatment. The treated water is then discharged into a clean pool and recycled for glass edge grinding, significantly reducing blockages and damage to the water outlet of the glass edge grinder, thereby extending machine service life and improving grinding efficiency. The glass dust slag processed by the reaction tank is discharged into the sludge pool, then pressed into solid glass plates by the filter press to prevent environmental pollution.

The high configuration type includes an air flotation machine after the reaction tank for secondary treatment to remove light suspended solids and pharmaceutical residues floating in the water. This secondary treatment ensures higher water quality, with minimal impact from raw water concentration on this system. It also reduces medication dosage by more than 10%.

If space for equipment installation is limited, you can opt for the mini type of edge grinding wastewater treatment system. Pumping edging wastewater into our integrated reaction tank results in recycled clean water for glass edging, while solid waste sediment is directly pressed into solid glass plates by the filter press.

3. Glass industry water treatment equipment configuration

4. Clear water quality after treatment

| No | Water inlet quality | Test item | Clear water quality |

| 1 | Edging wastewater | PH | 7~8.5 |

| 2 | Edging wastewater | SS(mg/L) | <30 |

| 3 | Edging wastewater | COD(mg/L) | <20 |

| 4 | Edging wastewater | Chroma | <30 |

| 5 | Edging wastewater | AMMONIA(mg/L) | <15 |

5. More than 600 installation cases in total