1. Why choose wastewater air flotation machine?

In the modern industrial landscape, efficient wastewater treatment is of paramount importance. Among the various technologies available, air flotation machines have emerged as a vital solution, especially in the context of the glass industry.

The waste water air flotation machine is designed to handle a wide range of wastewater sources. It operates on the principle of air bubble attachment to suspended particles, causing them to float to the surface for easy removal. This machine incorporates advanced mechanisms to ensure optimal air dispersion and bubble formation, enhancing the separation efficiency of contaminants from the wastewater.

The wastewater air flotation machine, on the other hand, is specifically engineered to deal with the unique challenges posed by wastewater in glass industrial processes. It is equipped with sophisticated control systems that allow for precise adjustment of operational parameters such as air flow rate, pressure, and bubble size. This customization ensures that the machine can effectively treat wastewater with varying compositions and pollutant loads.

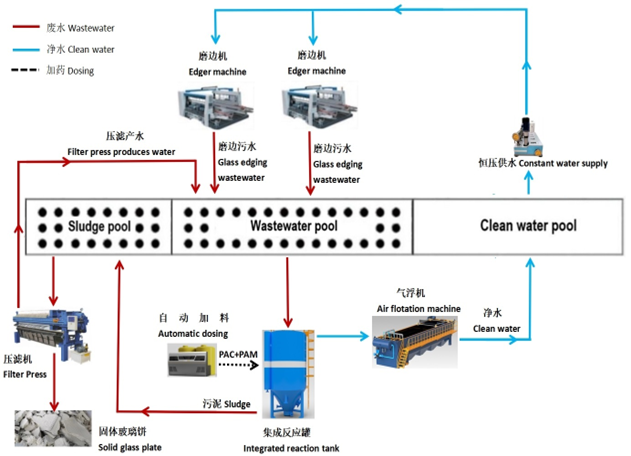

2. Glass industry air flotation machine solution

The glass industry air flotation machine is tailored to meet the demanding requirements of the glass manufacturing sector. Glass production generates wastewater containing various impurities such as glass particles, chemicals, and oils. This specialized air flotation machine is designed to handle these contaminants efficiently, minimizing the environmental impact and ensuring compliance with strict industry regulations.

One of the key features of these air flotation machines is their energy efficiency. They are designed to consume minimal power while delivering high-performance treatment. The use of innovative materials and components also contributes to their durability and low maintenance costs, making them a cost-effective choice for long-term operation.

The design of these machines incorporates state-of-the-art technology to ensure seamless integration into existing wastewater treatment systems. They can be easily installed and operated, with intuitive control interfaces that enable operators to monitor and adjust the treatment process in real-time.

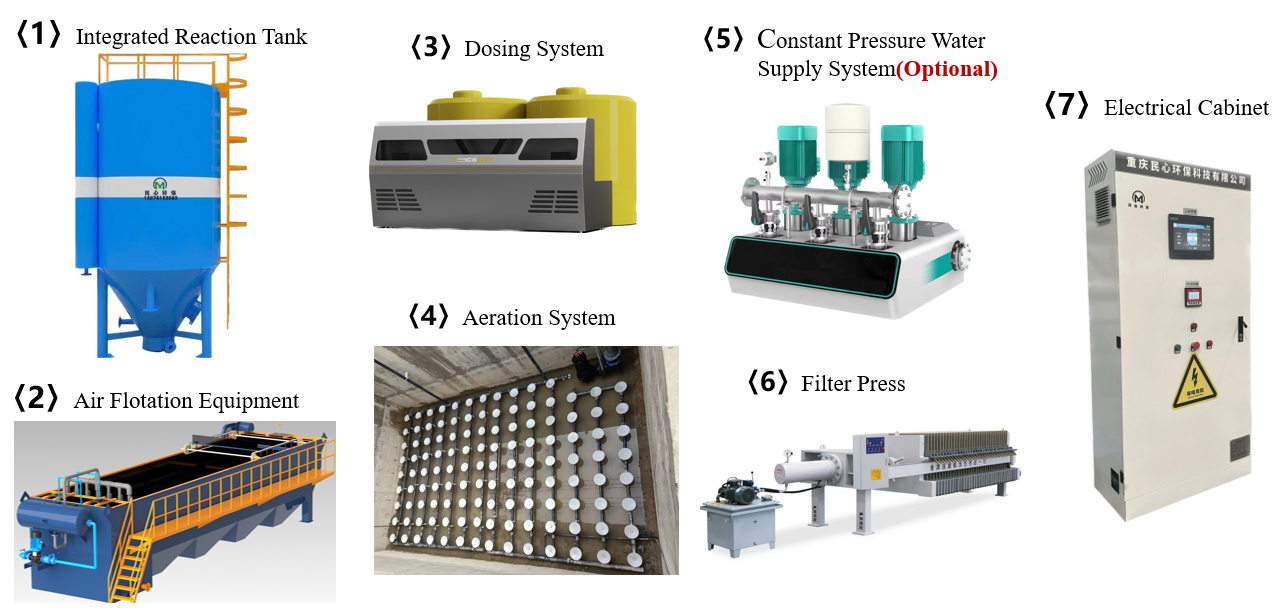

3. Wastewater air flotation machine configuration

4.Treatment water quality effect

| No | Item | Water inlet quality | Purified water quality |

| 1 | PH | Edging wastewater | 6~9 |

| 2 | SS(mg/L) | Edging wastewater | <30 |

| 3 | COD(mg/L) | Edging wastewater | <60 |

| 4 | color | Edging wastewater | <30 |

| 5 | AMMONIA(mg/L) | Edging wastewater | <25 |

5. More than 600 installation cases in total