1. Why choose waste water filtration system?

A. Untreated wastewater from the edging process leads to inadequate cleaning of the edge grinding machine, resulting in reduced light transmittance after glass tempering, increased formation of tempering pits, and shortened service life of the ceramic roller.

B. Untreated edging wastewater can cause frequent blockages in the water inlet pipe of the edging machine, leading to operational disruptions for cleaning purposes, burning of glass edges, and a 31.8% reduction in grinding wheel lifespan.

C. The high concentration of glass powder in untreated edging wastewater can result in fine scratches on coated glass surfaces and large plate glasses during the edge grinding and cleaning process.

D. Untreated edging wastewater increases the frequency of water changes required for the cleaning machine, resulting in unnecessary costs.

E. The circulation pool used for edging needs to be cleaned every six months, which incurs high costs and poses challenges for water treatment management while causing production downtime.

F. Direct discharge of untreated edging wastewater fails to meet national standards.

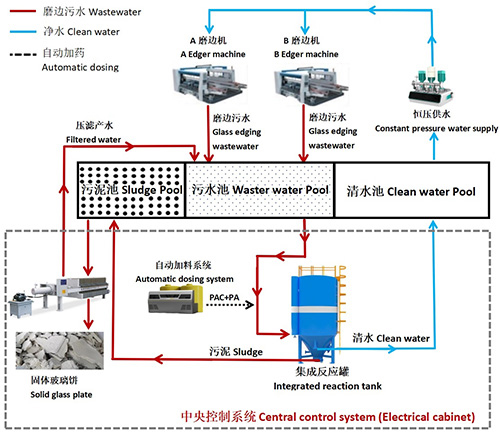

2. Treatment process of waste water filtration system

The treatment process of this system is meticulously designed to efficiently handle the wastewater discharged from a diverse array of glass processing machinery, including but not limited to multiple glass edger machines, beveling and mitering machines, drill machines, sanding machines, and CNC equipment. This wastewater is systematically collected and directed into a specifically designated wastewater pool.

To ensure optimal conditions within the wastewater collection pool, an advanced aeration device is strategically installed at its bottom. This device serves the crucial purpose of maintaining a dynamic environment, preventing the glass fines from settling and accumulating at the base of the pool. Such a mechanism helps to keep the contents of the pool well-mixed and homogeneous.

The integrated reaction tank is a highly sophisticated component that ingeniously combines several critical functions, namely water pumping, precise dosing, efficient reaction, and controlled drainage. Through this seamless integration, the treatment process becomes streamlined and highly effective.

The treated clean water, having undergone the rigorous purification process, is carefully discharged into the clean water tank. This clean water is then recycled for utilization in the glass grinding edge operations. Such a recycling approach offers significant benefits, notably by significantly reducing the likelihood of blockages and damage to the water outlet nozzles of the glass grinding edge machines. Consequently, it leads to an extension of the machine's service life and a notable improvement in the grinding efficiency.

The solid waste resulting from the treatment within the efficient integrated reaction tank is methodically discharged into the sludge pool. Subsequently, a powerful diaphragm pump is employed to transfer this sludge to a filter press. Here, the sludge is compressed and transformed into a solid glass plate. This transformation not only simplifies the subsequent handling process but also ensures that the solid glass plate can be dealt with directly, thereby effectively avoiding any potential environmental pollution and adhering to strict environmental protection standards.

3. Glass industry water filtration system configuration

4.Treatment water quality effect

| No. | Item | Water inlet quality | Purified water quality |

| W | PH | Edging wastewater | 6~9 |

| 2 | SS(mg/L) | Edging wastewater | <30 |

| 3 | COD(mg/L) | Edging wastewater | <60 |

| 4 | Color | Edging wastewater | <30 |

| 5 | AMMONIA(mg/L) | Edging wastewater | <25 |

5. More than 600 installation cases in total